The air flow meter (AFM) relocation is one of the most popular modifications to do to the e15et engine and is one that most choose to do early on in the modification process. The biggest problem with moving the afm is the loss of the factory cold idle sensors. This can generally be remedied by blocking off both ends of the infamous “log” and plumbing in the tappet cover breather. However for some of us who want to get rid of the “log” there is now another cheap technique we can carry out to help retain some of the properties of the cold start idle. Damien D explains the way he got around such a problem:

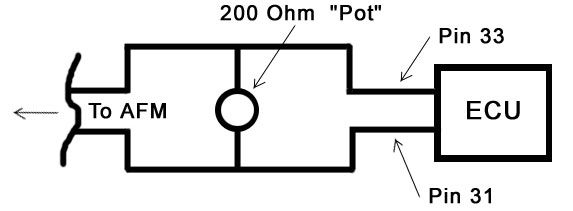

After doing the much talked about AFM relocation (before it was a popular upgrade), I lost all the idle air control and some of the emissions on my engine. This resulted in the engine requiring warming up in the morning as the ECU could no longer control the amount of ‘idle up’ air being injested by the engine. To counter this, I played around with the idle speed, timing and so forth. I got it running ok when it was cold, but then it would warm up and the revs would sit at around 2000rpm or so. I had to do something about this. So I traced some of the AFM wires to the ECU and figured that I could fool the ECU by changing that load input. By doing this, I am now able to have an acceptable cold engine idle speed, and while the engine warms, I am able to slowly adjust that idle speed till it’s no longer required. I use a 200ohm linear trim pot in parallel with the original wiring to change the fueling. Mine is connected to the out put of the AFM itself. By doing this I have inadvertently limited the adjustment I am able to make due to the fact that the AFM is very non-linear in it’s out-put. Which basically means that I am only able to change idle and up to 0 manifold vac at low revs. Which is all I wanted anyway.

Damien D

There are other sensors which signal is able to be altered this way:

- Air temp sensor

- Coolant temp sensor

and possibly others that I’m unaware of. The only problem with these are that if you modify the signal out of them, you change all the fueling in all conditions (other than if the engine is running lean due to the size of the fuel system), which can be extremely dangerous if you don’t know what you are doing. After consulting the manual, it seems that changing the signal from these will be of greater benefit when the engine is already at operating temp, rather than when its cold.

The other benefit of the setup I’m running is, with the use of a mixture meter I can get quite good fuel consumption on the Hwy, by leaning out light throttle mixtures. The out-put pins to the ECU are pins 31 and 33, all that needs to be done is to run the 200-ohm pot in parallel with the factory wiring. The concept is quite simple, but may take a little mucking around to get the exact results that individuals are after.”

You must be logged in to post a comment.